Product Description

Short and medium distance, indoor and protected environments.

As a riser, or general purpose cable.

Interconnection of distribution boxes, of the distribution boxes and customer equipment, and between floors.

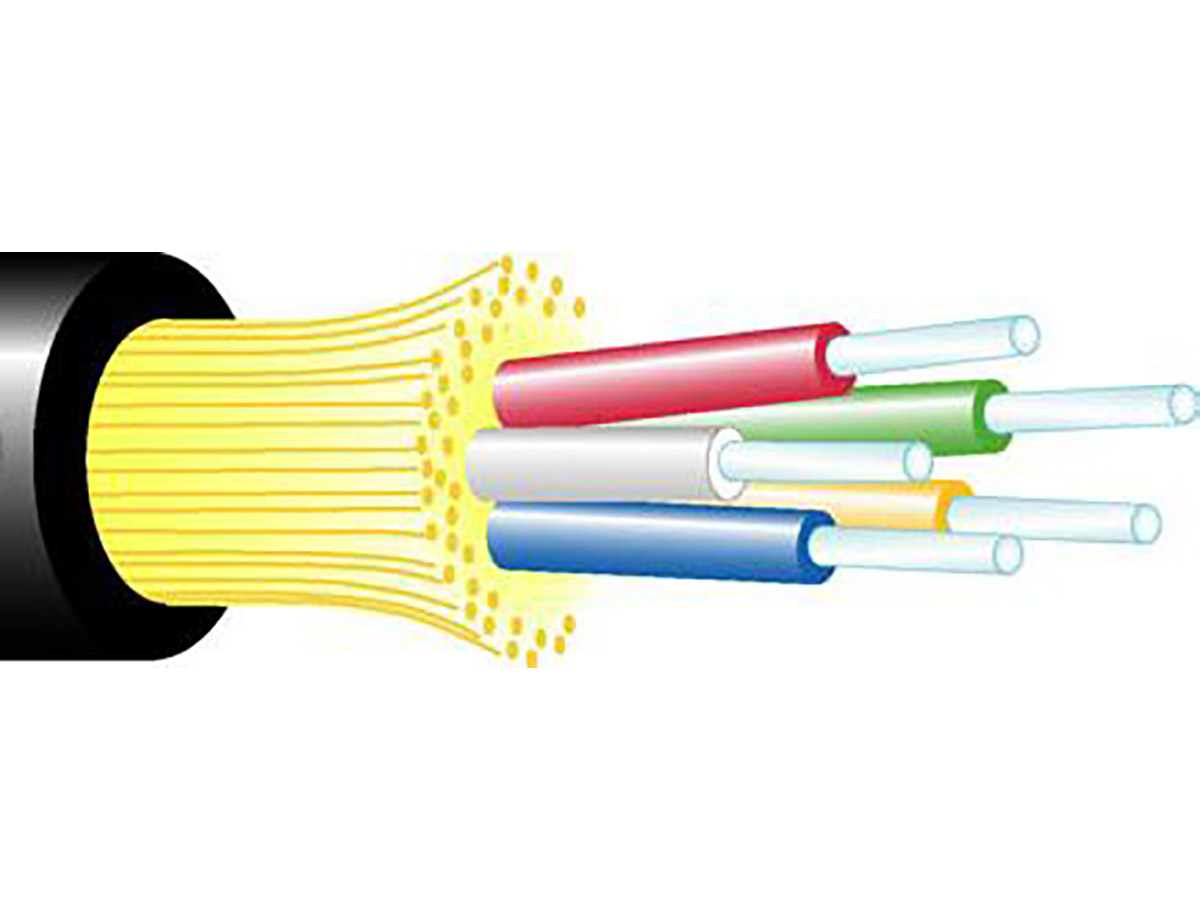

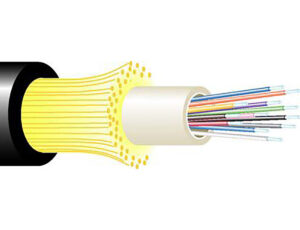

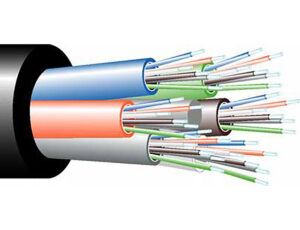

The cable contains 4 to 288 fibers individually buffered to 0.9 mm in a tight or semi-tight construction and coded.

The cable structure depends on the number of fibers:

In the 4-to-24-fiber cables (MTA series), the individual fibers are stranded and protected by aramid yarns and a PVC or HFFR jacket.

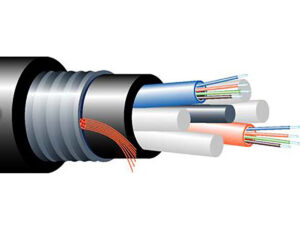

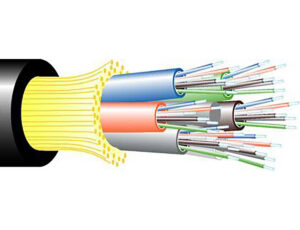

When more than 24 fibers are required sub-units are employed which are laid helically along the cable axis. Each sub-unit contains 4 to 12 fibers, aramid yarns and a PVC or halogen-free flameretardant sheath. The sub-units are then stranded around a central element made either of additional sub-units or a central filler.

- MTA – up to 24 fibers without sub-units

- MTB – 26-96 fibers in 4 fiber sub-units

- MTC – 98-144 fibers in 6 fiber sub-units

- MTD – 146-192 fibers in 8 fiber sub-units

- MTE – 194-288 fibers in 12 fiber sub-units

A wide range of jacket and armoring options is available: PVC, HFFR, corrugated steel , fiberglass,

aramid yarn, and more. The steel armored option is available in conjunction with a PE or HFFR

jacket. A ripcord is located under the jacket to facilitate removal.

- Cables tested according to TIA/EIA-455 and IEC-60794-1-2. For details see Test Methods Table

- Cables ordered with HFFR jackets meet IEC-60332-1 standard

- Cables meet or exceed Telcordia (Bellcore) requirements for indoor plant cables (GR-409)

- On request cables meeting the IEC-60332-3 can be supplied

- Available in constructions meeting UL 1666 (Riser rating)